Web Menu

- Home

- About

- Product

- (PP) Polypropylene Granules

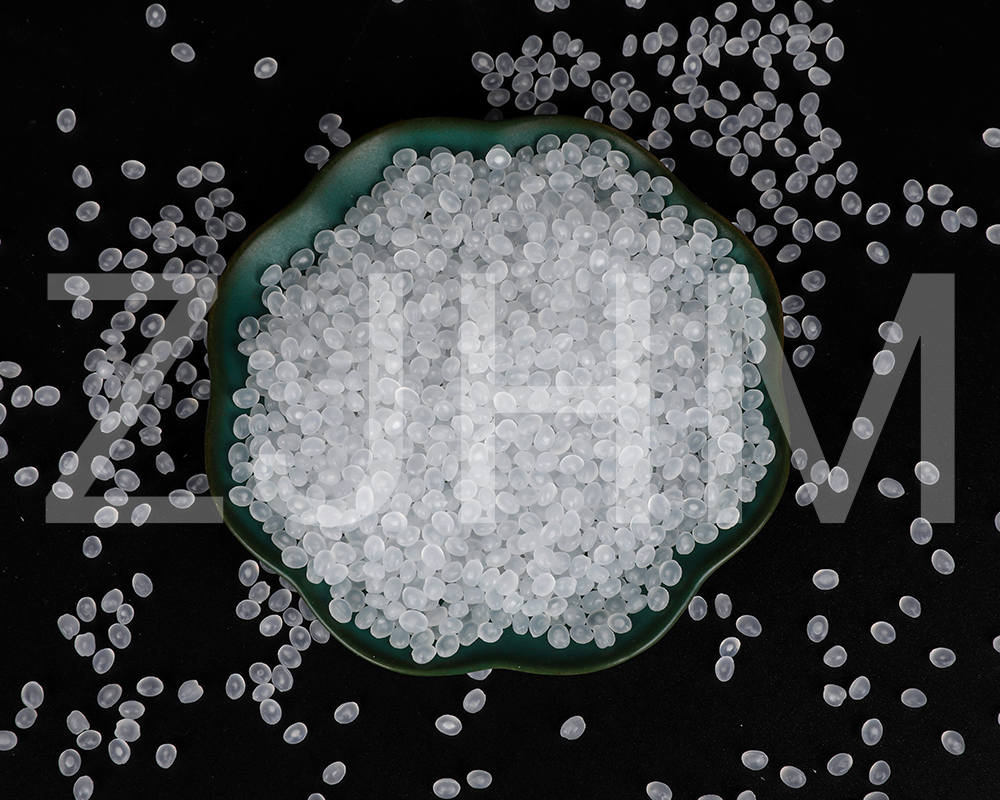

- (LDPE) Low density polyethylene Granules

- (LLDPE) Linear low density polyethylene Granules

- (HDPE) High-density polyethylene Granules

- (GPPS) Polystyrene Granules

- (HIPS) High impact polystyrene Granules

- (ABS) Acrylonitrile butadiene styrene Granules

- (POM) Polyformaldehyde Granules

- (PC) Polycarbonate Granules

- (PVC) Polyvinyl Chloride Granules

- (PET) Polyester Chip Granules

- (EVA) Ethylene Vinyl Acetate Granules

- (TPE/TPR) Thermoplastic Elastomer

- ABS recycled material

- News

- application

- Contact

English

English

Español

Español

+86-0571-61070797

+86-0571-61070797